Lee este blog en español haciendo clic aquí.

Throughout the course of my career, I've often been involved with projects pursuing sustainability goals like LEED (Leadership in Energy and Environmental Design) certification across the United States. The latest part of my career has involved Lean Construction and LEED.

Q.) Are there mutual connections or equivalents between Lean and LEED?

A.) Yes.

Many project teams may include some LEED AP (Accredited Professional) or LEED Green Associate team members. These professionals have demonstrated learning and experience sustainability certification-seeking projects. LEED APs complete must even complete 30 hours of continuing education units every two years. LEED Green Associates complete 15 hours every two years. Attending conferences, workshops, or completing online lessons. This ongoing education enables easier team collaboration among clients, design professionals, and builders, keeping up with changes in the standards and industry.

Lean practitioners have various learning options, from informal on the job to very structured certification programs. Here is a shortlist from searching the web.

- Certificate of Management - Lean Construction (AGC CM-Lean)

- Agile Certified Practitioner (PMI-ACP)

- Lean Six Sigma (LSSI Academy)

- Lean Construction Institute Certificate Courses (LCI Training)

- Scrum in Design and Construction (Scrum Inc. Course)

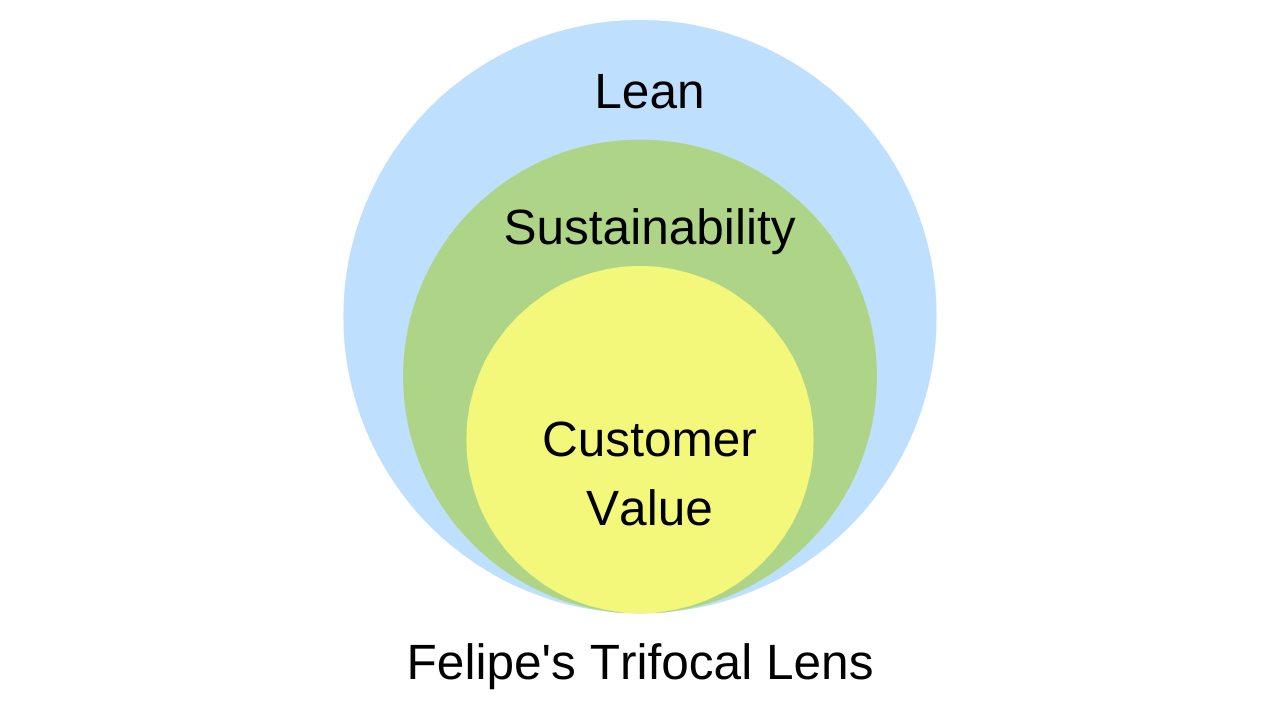

Disclaimer: I'm biased and see everything through a Lean lens focused on customer value. If you watch or listen to The EBFC Show, this image below should make sense. If not, drop me a question here, and I'll recommend some episodes. All the white area behind the Lean circle is the Scrum universe.

Here are the five most asked questions I get about LEED and Lean.

- Where did Lean come from?

- What does Lean mean for the construction industry?

- What are sustainability principles?

- What is Lean Thinking?

- Do Lean and sustainability intersect?

1. Where did Lean come from?

Lean is the term coined to describe the management philosophy and practices made world-famous by the Japanese automaker Toyota. Credit for “Lean” as we use it today goes to John Krafcik, who was part of the research team responsible for the book The Machine That Changed the World authored by James P. Womack, Daniel T. Jones, and Daniel Roos. According to Mark Graban, Krafcik said, “[Toyota]… is “lean” because it uses less of everything compared to mass production – half the human effort in the factory, half the manufacturing space, half the investment in tools, half the engineering hours to develop a product in half the time. Also, it requires less than half the needed inventory on site, results in many fewer defects, and produces a greater and ever-growing variety of products.” Lean continues to describe the methods and thinking of Toyota most commonly. Read Mark's original post here.

Jeffery Liker authored The Toyota Way, which summarizes years of direct research describing the principles and practices at Toyota that sustain it forward by continuous learning by solving problems with the people closest to the issues. Its members work to deliver customer value while minimizing waste. A key principle of Lean organizations includes respect for people, both their value creators and customers. Organization-wide applied lean principles significantly impact how customer value is created and delivered.

Lean is a mindset of learning derived from sense-experience centered on a deep respect for people value.

2. What does Lean mean for the construction industry?

Lean Construction starts with individual project team adoption that grows toward organization-wide implementation. Culture guides the speed and ease of adoption. I look for examples of Lean Construction principles.

- Respect People

- Deliver Value

- Create Flow

- Remove Waste

- Continuously Improve

- Optimize the Whole

In my experience, these synergistic values enable work to deliver easier, better, and faster. I also actively encourage and coach teams on Lean tools that promote continuous improvement with a focus on the Last Planner System of Production Controls, A3 Thinking/Problem-Solving, and Scrum. Resistance vanishes with my enthusiasm and the team's recognition of improved collaboration, communication, better team experiences, and learning.

Lean is not a tool, task, or extra work. It is a mindset of continuous learning.

3. What are sustainability principles?

Environmental sustainability means that renewable resource use rates, pollution creation, and non-renewable resource depletion don’t continue indefinitely. Human social and economic actions work in harmony with the environment. Sustainability has evolved in business to describe how organizations and people impact the environment positively and negatively. The environmental impacts are from the people processes involved in materials resource utilization processes such as manufacturing and construction. Buildings change the local environments throughout their multi-decade operations. International supply chains invoke sustainability thinking beyond the physical building location. Sustainability significantly impacts resources to make and operate buildings and people living in communities around the world.

The construction industry directly impacts local and global environments. We live, work, and play on one planet. We are responsible for serving as stewards of the environment entrusted to us for the next generations to follow.

Sustainability principles include:

- Respect People and Planet

- Deliver value

- Create Flow

- Remove Waste

- Continuously Improve

- Optimize the Whole

😄 Do you understand my disclaimer better now?

4. What is Lean Thinking?

Lean embodies a mindset as explained in Lean Thinking: Banish Waste and Create Wealth in Your Corporation. A Lean perspective frames the whole set of processes that deliver a project, especially its goals. Lean practitioners focus on the big picture from the context of customer/stakeholder value and non-value-adding work. Anything that doesn't support a project’s goals doesn’t add value and warrants minimization or elimination. Lean practitioners are problem solvers working beyond the limitations of the “just another job” mindset. This approach empowers people to continue creating more customer value.

5. Do Lean and sustainability intersect?

Yes. Sustainable construction practices center around environmental issues that affect people. Lean Construction principles start and stop with people. The ideas are not mutually exclusive; rather, they are complimentary. A sustainable building project may or may not include applied Lean principles. Likewise, a Lean project may or may not include sustainable building practices, although high-intensity Lean projects often do.

Respect

In my experience, Lean and sustainability principles are interwoven. Focusing on increasing customer value, improving flow, decreasing waste, and continuously improving builds greater respect for all project stakeholders. Lean is ultimately about people transforming their work, not just making projects more efficient and sustainable; those are consequences of continuously improving their work. Trying to improve how you build, how sustainably you build, or a combination of both equates more respect for people and the planet.

Lean and Scrum

After years of learning about and practicing with lean tools, I recognize it as a mindset. Dr. Jeff Sutherland, Scrum co-creator, often remarks that Lean is a parent of Scrum. In my training to become a Scrum Master, I learned from Jeff that the work of Takeuchi and Nonaka on Lean and the Toyota Production System paved the way for the Scrum framework as we know it today. If you are practicing Scrum, you are practicing Lean.

How are you using Lean, LEED, or Scrum? Let me know if I can encourage you. Drop me a line here.