One Hour That Changed Everything

One Hour That Changed Everything

A Construction Scrum Coaching Story

Adam called me with a problem I hear all the time.

He runs three landscape construction crews. Good people. Hard workers. Jobs getting done. But something felt off.

"I'm doing the work," he told me. "But we're missing something."

That one sentence told me everything.

The Familiar Pattern

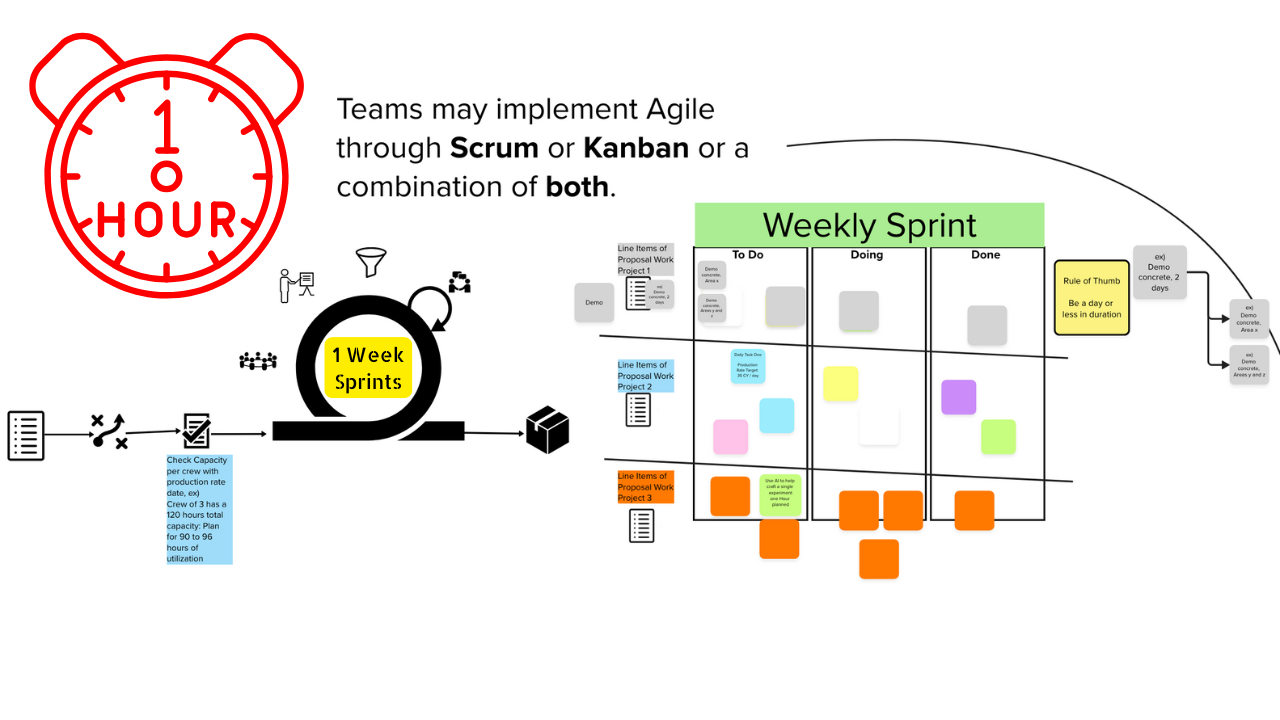

Adam had built the bones of a Scrum system. Friday retrospectives were happening. He had a Scrum board up and running. His teams were showing up, doing the work, and going home.

But sprint planning? That part hadn't started yet.

And without planning, crews can be left guessing. They knew which job site to show up at. They didn't always know which specific tasks needed to be done that day, in what order, or with what production expectations.

Sound familiar?

I've seen this pattern in companies ten times Adam's size. Activity without alignment. Effort without visibility. People working hard but not together.

The Math That Changes Everything

We started with a simple question: How much capacity do you actually have?

Adam's crews run three people each. Three people times 40 hours equals 120 hours per week. On paper.

But this is construction. This is landscaping. Weather happens. Site conditions happen. Equipment breaks. Someone calls in sick. Reality happens.

So we don't plan for 120 hours. We plan for 90 to 96.

That 20% buffer isn't lost productivity. It's respect for the truth of the work.

I told Adam something I've learned the hard way over decades in this industry:

If you plan for 120 and hit 90, you failed.

If you plan for 90 and hit 96, you're ahead.

That mindset shift alone can transform how a team feels about their work.

Making Work Visible

Next, we designed a board. One board for all three projects, with swim lanes for each crew, color-coded so anyone can see who's doing what in a glance.

But here's the rule that makes the board actually work: every task should be a day or less.

If a task takes more than a day, break it down. If you can't break it down, you don't understand it well enough yet. That's not criticism—that's information.

This isn't micromanagement. It's making problems visible before Friday. Because in construction, if you wait until the end of the week to find out something went sideways, you've already lost days you can't get back.

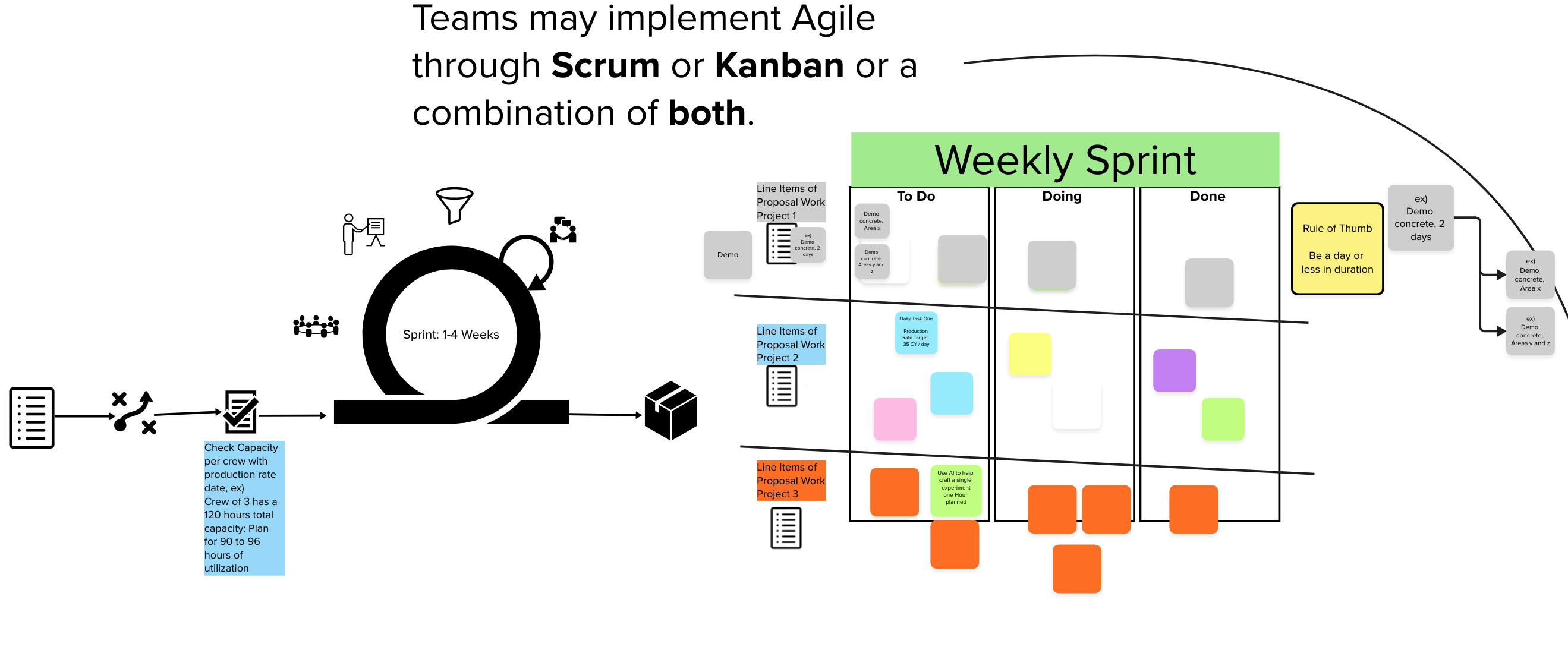

Seeing the Shape of the Work

Then we did something that I think really clicked for Adam. We mapped out his work visually across time.

This is a process called shape mapping. Lay out the months of a year or weeks in Adam's case. Stack your crews. Draw the activities—planting, drip irrigation, mulching—and watch the flow.

It's not a Gantt chart. It's a conversation.

Who's doing what? When do the handoffs happen? Where are crews going to collide if we're not paying attention? When should we plan for equipment and deliveries? Now we can see across three sites in a single second, without having to dig through pages of a schedule or scroll through chats.

Construction doesn't move in straight lines. Shape mapping lets you see the overlaps before they become collisions. It lets you plan the flow instead of reacting.

Closing the Loop

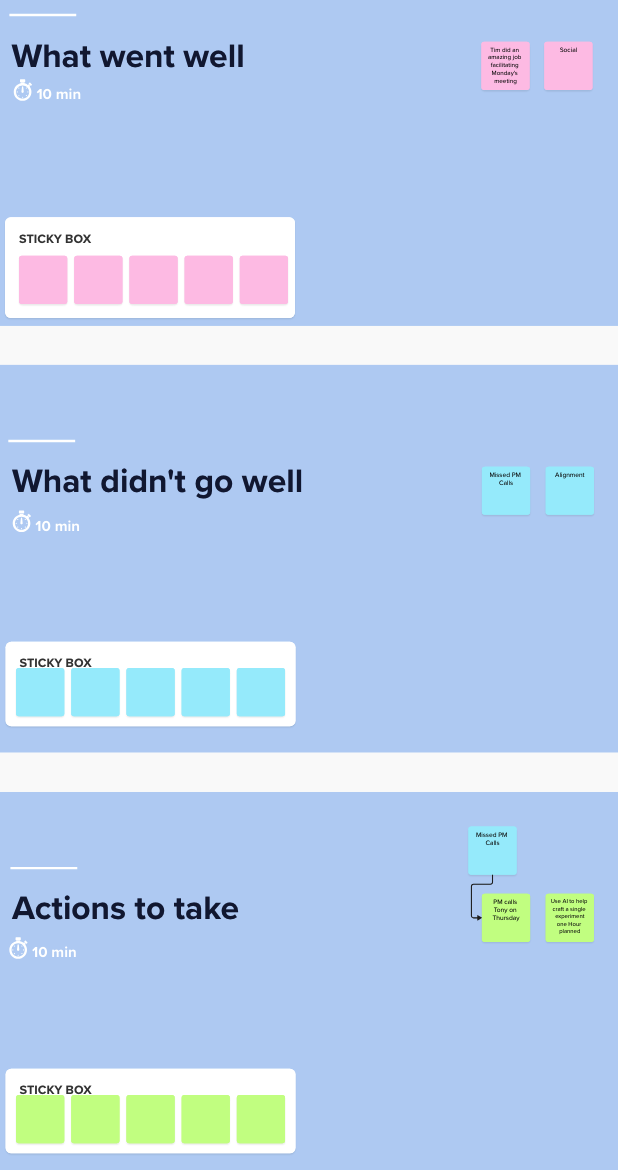

Adam's Friday retrospectives were already happening. But we tightened the format.

Forty-five minutes or less. Three questions.

What went well? Celebrate the wins. Name them out loud.

What didn't go well? No blame. Just honesty.

What experiment do we try next? And this is the one that matters most.

The Scrum Master—Adam, in this case—owns making that experiment happen. Not the crew. Not the foreman. The Scrum Master.

If you're not experimenting, you're not improving. And if you're not improving, you're just surviving. Nothing wrong with that unless you see the potential to make things easier, better, faster, and cheaper.

The Real Lesson

Here's what I told Adam at the end of our hour together:

- Don't try to implement everything on Monday.

- Pick one change. Maybe two. Let it stick.

- Build the habit first. Then add the next thing.

Scrum isn't a switch you flip. It's a system you grow into. And in construction, where conditions change daily and no two projects are alike, that patience is essential.

Adam left with a board design, a capacity number, a shape map, and a tighter retrospective format. But more than that, he left with a path forward.

One change at a time. That's how you build something that lasts.

This coaching call was part of the EBFC Scrum Community of Practice, where I work with construction teams every week on making Scrum actually work in the field. If you're ready to change how your team plans and delivers, join us.